When a chain fails in a mechanical system, it can cause costly downtime and safety risks. To prevent future failures, it is essential to conduct a thorough root cause analysis. Start by gathering all available information about the failure. This includes the exact circumstances and site of the breakdown, the operating conditions, maintenance records, and physical evidence of distress. Document the failure scene with detailed photographic evidence. Keep the broken components in their original state—avoid washing, polishing, or repositioning them prior to analysis.

Next, examine the fracture surface closely. Analyze the fracture for evidence of material fatigue, sudden overload, environmental attack, or progressive wear. Fatigue fractures often show beach marks or striations, while sudden overload results in brittle, uneven fracture surfaces. Chemical degradation manifests as rust spots or localized pitting, particularly in moist or corrosive settings. Measure the chain’s elongation and compare it to manufacturer specifications. Significant stretching often signals extended operation past its intended lifespan.

Review the chain’s installation and alignment. Poor alignment, incorrect tensioning, or worn sprockets create asymmetric loading that accelerates chain degradation. Check for lubrication issues—both insufficient lubrication and contamination can accelerate wear. Inspect the lubricant for particulates, sand, or moisture that erode surfaces.

Interview the operators and maintenance staff. They may have noticed unusual noises, vibrations, or performance changes before the failure. Worker insights frequently highlight early warning signs overlooked by technical diagnostics.

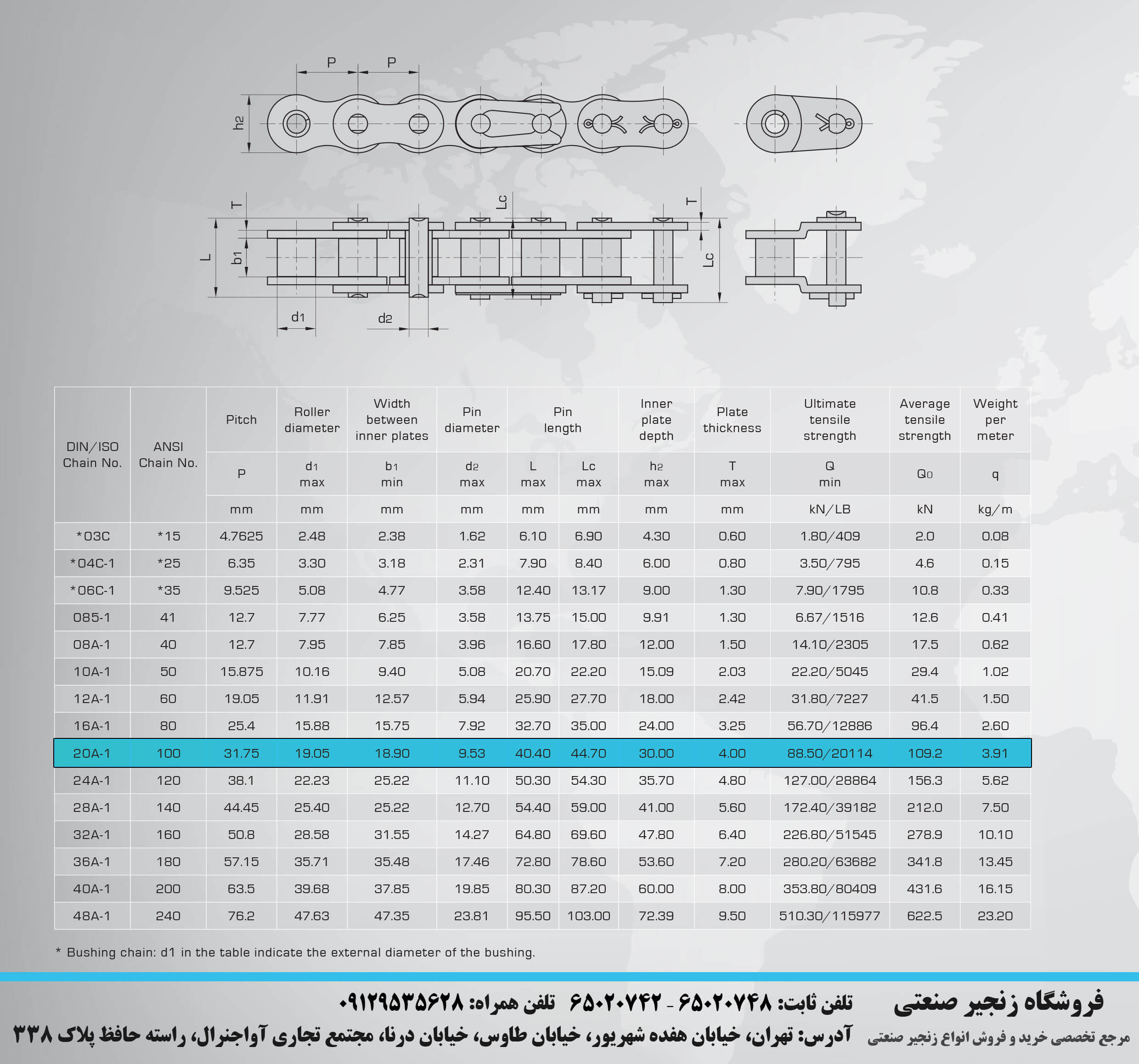

Compare the chain’s specifications to the application requirements. Was the chain appropriately rated for the actual workload, RPM, فروش زنجیر صنعتی and operating conditions? Choosing a chain with insufficient capacity for the task is a widespread oversight. Confirm that replacements are factory-approved and conform to manufacturer benchmarks. Non-genuine replacements are prone to premature failure despite proper usage.

Once all evidence is collected, piece together the sequence of events. Did one primary issue trigger the breakdown, or did multiple problems converge? Multiple stressors—contaminated lube, misaligned sprockets, and overburdening—may have acted together to cause collapse. Record results with precision, pinpointing the main failure driver and secondary influences.

Finally, implement corrective actions. Solutions may involve upgrading the chain model, refining maintenance protocols, realigning components, scheduling more frequent checks, or educating personnel. Monitor the system after repairs to ensure the fix works. The true worth of RCA lies in its ability to drive sustainable change. Regularly review maintenance practices and update them based on new data to prevent recurrence.